Header image is at Alice Cooper concert. It has been a VERY long time since I’ve posted. I kept meaning to write something up quickly, but sometimes even just a litle is too much.

So, the biggest reason for my delay is depression. I’ve had a few breaks here and there, but I get so wrapped up doing things in those times I completely forget about posting. But depression has been the real drain of my ability to post. But, here are some of the other things that contributed to keeping me away.

Sister-in-law’s wedding

My wife’s sister decided to have a faux wedding ceremony here because her fiance’s family is going to be heading to Texas for the official ceremony. She figured that because her fiance is Muslim and Pakistani some of the people in her family that are important to her would ruin the Islamic cerimony planned for Texas.

Since she planned her ceremony in Utah to take place in my back yard, it was my responsibility to get the yard ready and clean all the house that would be publicly accessed. This all took place shortly after my last post and kept me pretty busy. I was also tapped to write the ceremony. That didn’t take me too much time, about 3 hours in a single night. I asked my mother-in-law to give feedback and they just went with my first draft. Overall it was pretty fun.

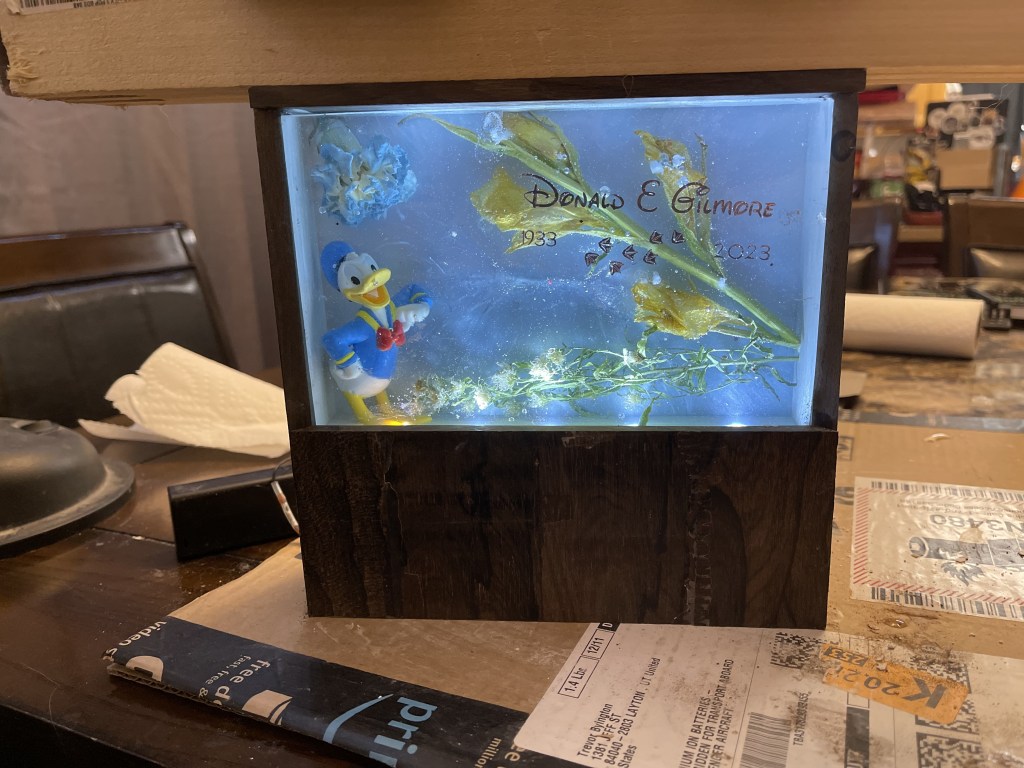

Passing in the family

My wife’s grandfather has always been a kind and upbeat guy, but he had been plagued with nearly every affliction diabetes can inflict. In his 60s he suddenly lost all his hair, even his eyebrows. About 10 years ago he lost his left leg below the knee. His favorite way to joke about this was when someone asked how he was doing he would respond, “All right and half left.” He always joked that all he wanted for his birthday was another birthday. In 2023, his birthday came shortly after my sister-in-law’s wedding ceremony.

Only a matter of days after his birthday he ended up in hospice before passing away. It was fortunate that there was enough forwarning for most of the family to arive, but even we only made it half an hour before he passed. He was the person my wife felt most filled the role of her father, so she was crushed by his death.

We all helped with the funeral and helping my wife’s grandmother get through the loss of the man she’d spent over 60 years of her life with. She eventually decided that their home was too large and, because she was mostly wheelchair dependant, had too many stairs. She had all of us, her children and grandchildren and spouces, help prepare her house for sale. A few of us also went to Saint George, UT, to get her manufactured home sold. It took over a week of dedicated work by a rotating crew of 4-6 people to pack up her house. It seems like a lot, until you are reminded she’d lived in that house for more than 60 years, of course she was going to fill it up with a lot of memories.

We spent the rest of 2023 helping to keep her company in her new home.

New animals

Anyone who knows me knows I love animals, and most animals like me even if it takes a short warm up period for us to become friends. Well, 2023-2024 was a crazy period of animals moving into our home.

Parrots

A parrot is identified by a curved beak and it’s feet having two toes forward and two toes backward. So yes, Cockatiels and Budgerigars (budgies) are parrots. If you don’t spend a ton of time looking up random information, a budgie is what most americans call a parakeet, but in fact, parakeet is any one of a large number of small to medium parrots, which does include budgies.

On Black Friday we adopted a whiteface cockatiel named Ash. We kept the name because it fit with her black and white coloring. She’s a bit antisocial so we call her our Gothitiel.

Since then we’ve also adopted a cockatiel with more traditional coloring that we named Hazel. She’s a little bit more social and is actually getting Ash to come out of her shell a bit.

And, though I don’t have a picture of them, we also adopted 6 budgies. Peridot, Opal, Pearl, Aquamarine, Quartz, and Diamond. Each is named according to their coloration. I love watching them play, they are silly, and when they fly the have beautiful tails. We let all of our birds spend a good amount of time out of their cages, so we see how their flying improves as their feathers grow back from being clipped and they get more practice flying around the room and playing together.

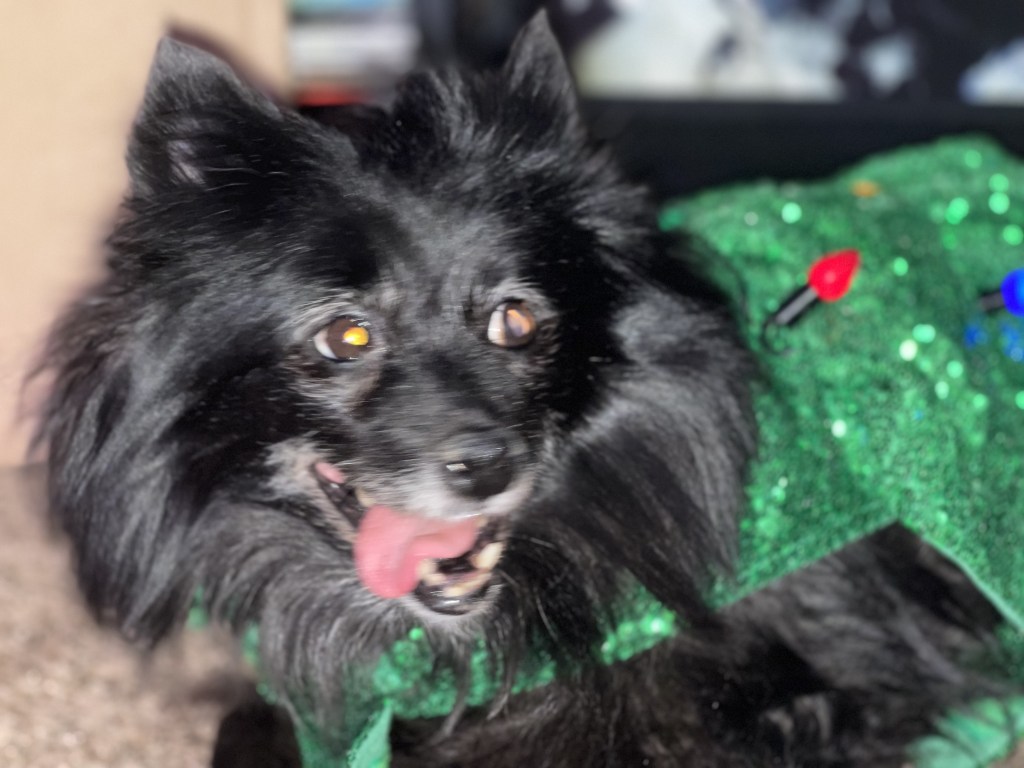

Pomeranians

I love dogs of all breeds, but fluffy dogs have always taken a special place in my heart. My dad used to raise Chow Chows, and their silly personalities, ferocious loyalty, and huggable necks just got imprinted on me as the traits of an amazing dog. Anyway, Pomeranians have been my choice of fluffy dog throughout my adult life. Since 2004 I have never been without one, and after 2006 we have had at least two.

We adopted Lady as a rescue pup when she was about 10. She had been as a breeder for a puppy mill, and from the way she behaved, we could tell a lot about how she was treated. It was not good. But she was a sweet dog. The sweetest you could ever meet. And all we hoped to do is give her the best life in the time she had left. So there was expectedly a period of mourning when she passed away.

But shortly before lady passed away, we adopted a literal demon and named him Remi. He is a cutie, and people always mention how handsome a pup he is, but he’s a brat like no dog I have ever met.

He’s cute, right? But he has an agression problem that leads him to attack me without warning and with little provocation. My hands and forearms are covered in little teeth marks so we have to keep him away from other people while we are trying to get him looked at and figure out how to help him get past that.

And he wont stop attacking Whisper. Whisper is my support dog and has gotten me through several suicidal times. He is the smallest and lightest of all the pomeranians we’ve adopted, weiging in at 6.5 lbs.Remi will tackle him and drag him around playing and seconds after breaking them up Remi will be right back to attacking Whisper. And Whisper is too gentle to fight back. So when Remi is awake, I have to spend my attention on making sure he’s not being a jerk again.

Additional crafting and projects

Jewelry

I’ve been working on and off to get some skill in jewelery making. I started with tumbling stones, but getting impatient with the long times it takes to tumble a batch, I started saviing up for a new machine. A cabbing machine. I have fun cabbing, but the only space for me to work is tucked back in the back of the utility/laundry room, right under the drying rack for hang-drys. That means when there are clothes hanging I can’t cut cabochons or the clothes will get sprayed with gemstone infused water. So, not being able to get into it easily means I forget to do it a lot.

Still I keep trying to go at it, and have since got a diamond blade bandsaw so that I can cut slabs into shapes closer to the shape I’m going for, wasting less stone. Now I can get slabs at the gem fairs that come to town twice a year.

I’ve also been learning to do some cool wire wrapping. Here is the first one I made when I went to a workshop to learn how to get started.

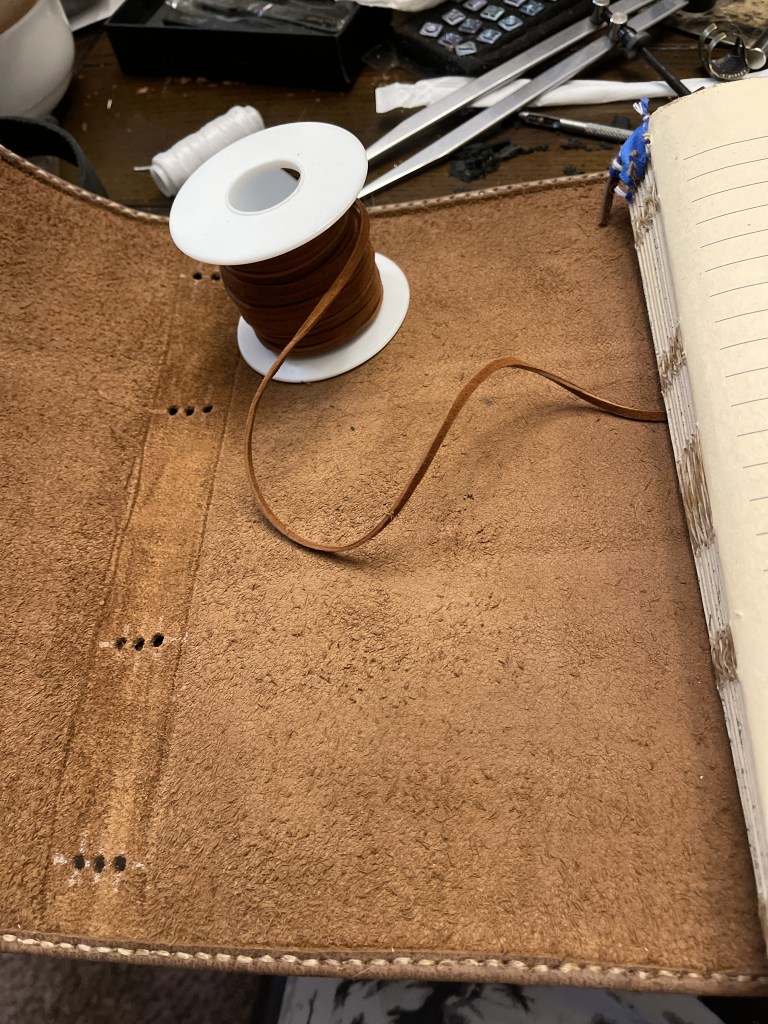

Book making

I’ve been making books for a while. My wife is wanting to start an Etsy store so I’ve been working on building up a little stock for her to post. I usually use a cloth or thin leather bound to a hard card stock for binding my books and I’ve gotten pretty quick at the whole thing. I can sew together a book block in just little over an hour.

While trying to figure out what my mom wanted for Christmas, she asked for a leatherbound journal for her coursework. I usually make codex style books, but she wanted something more like those leather journals you find on Amazon. So I had to study a few books and figure out how to bind one for her. That and manually lining the paper for the book took me most of December 2024, but I was really happy with the outcome.

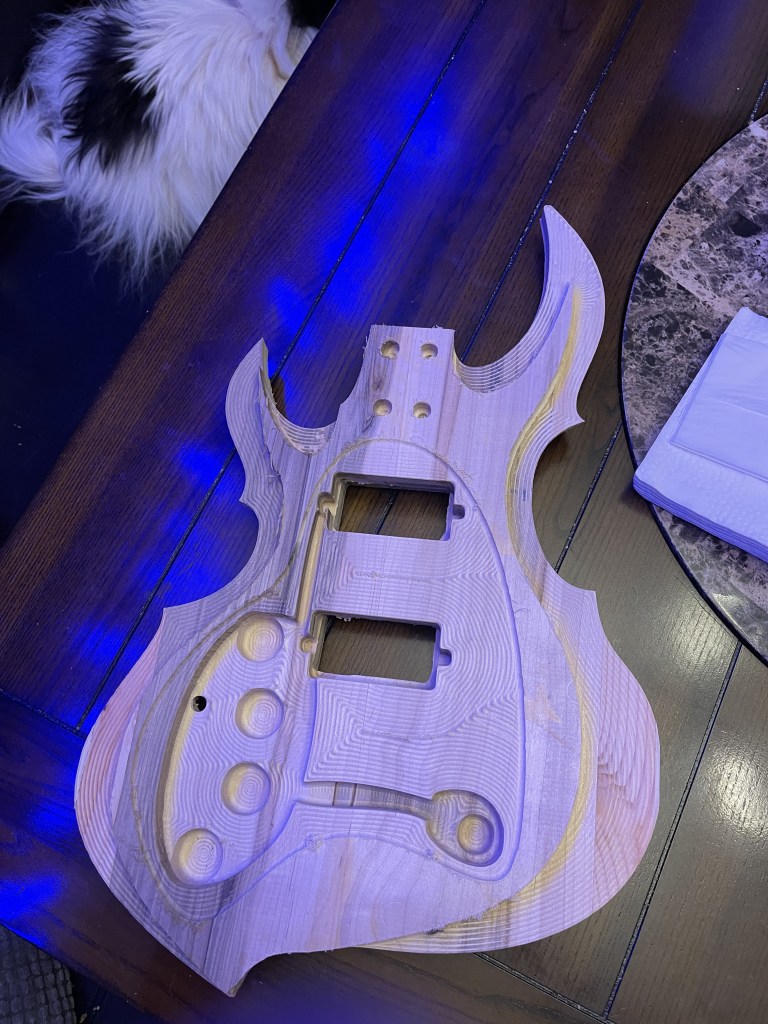

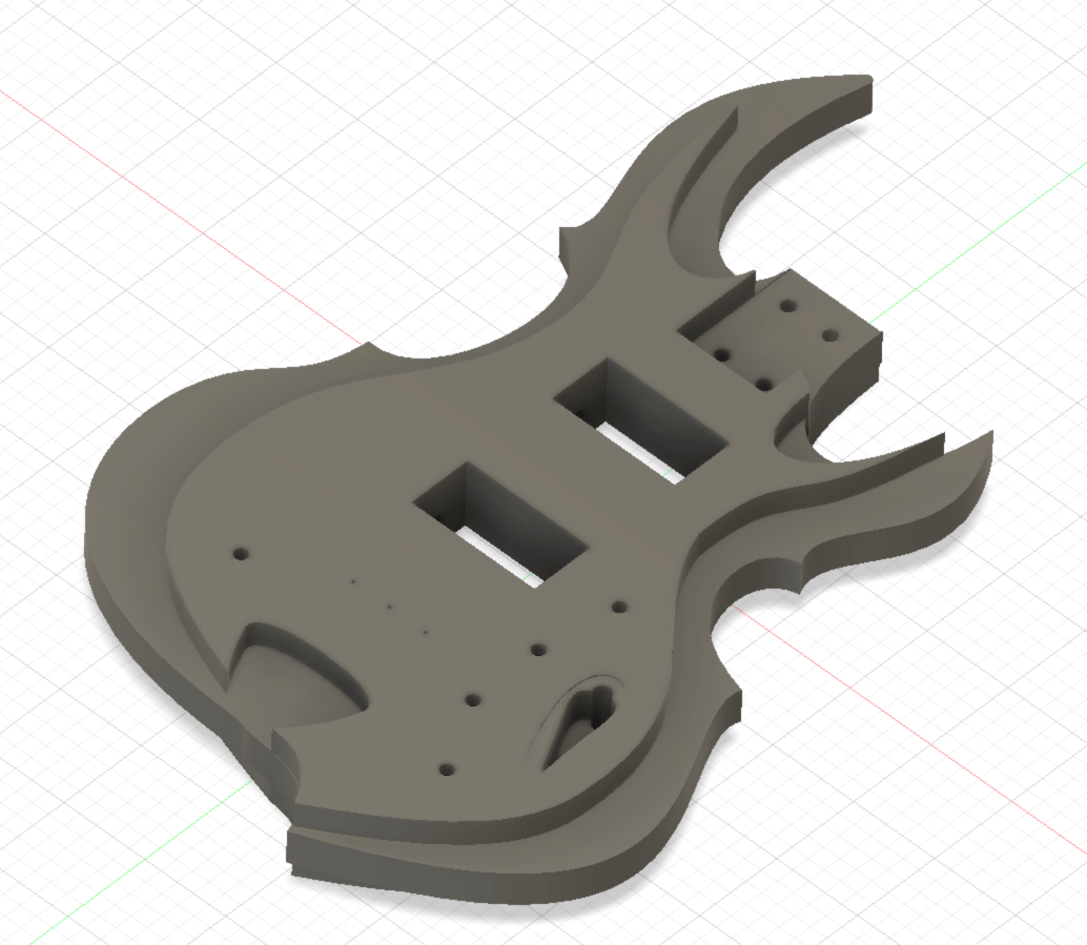

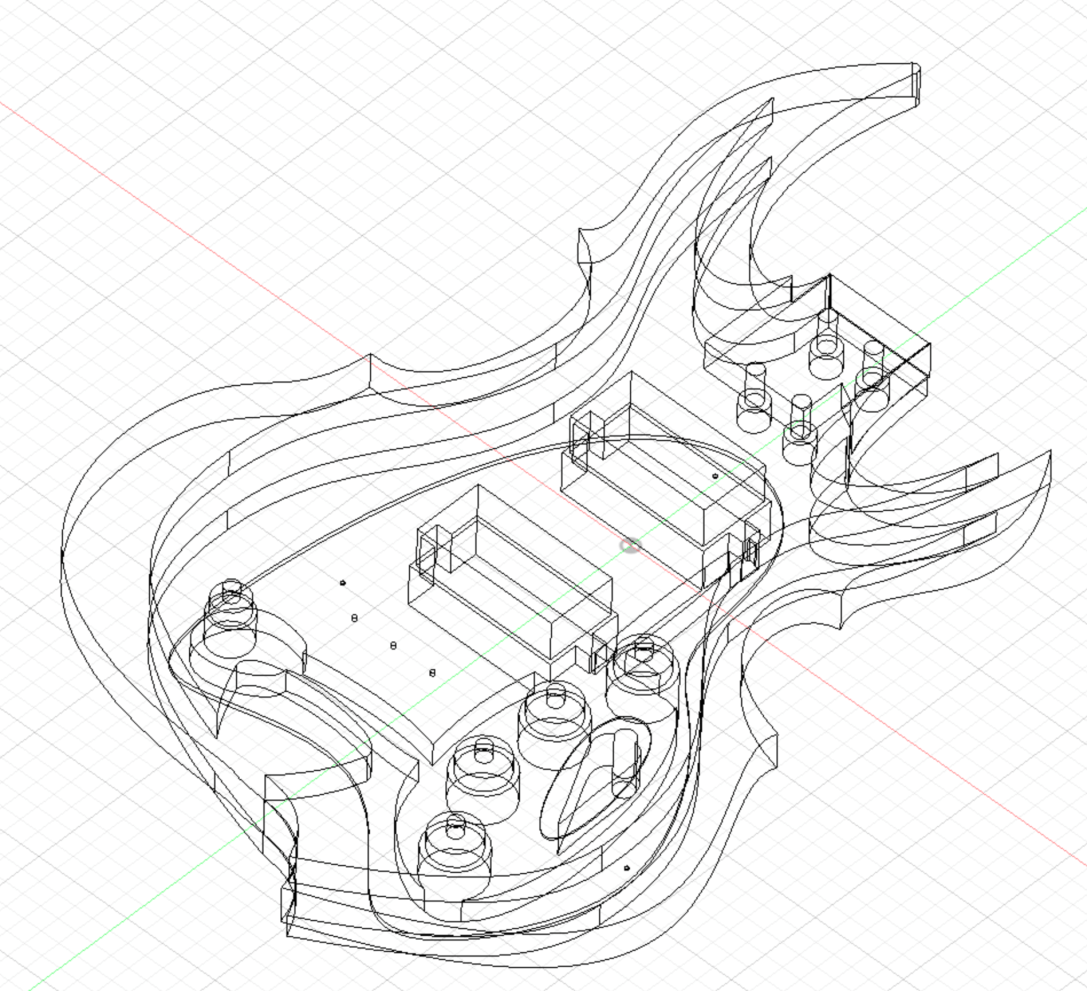

Wood projects

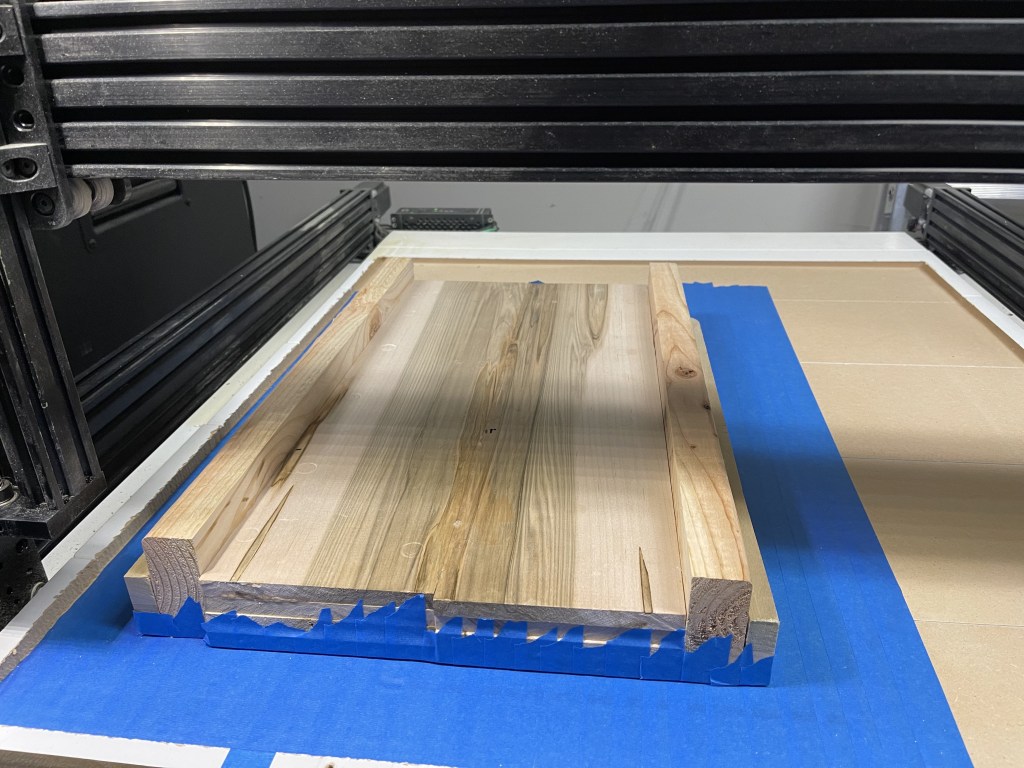

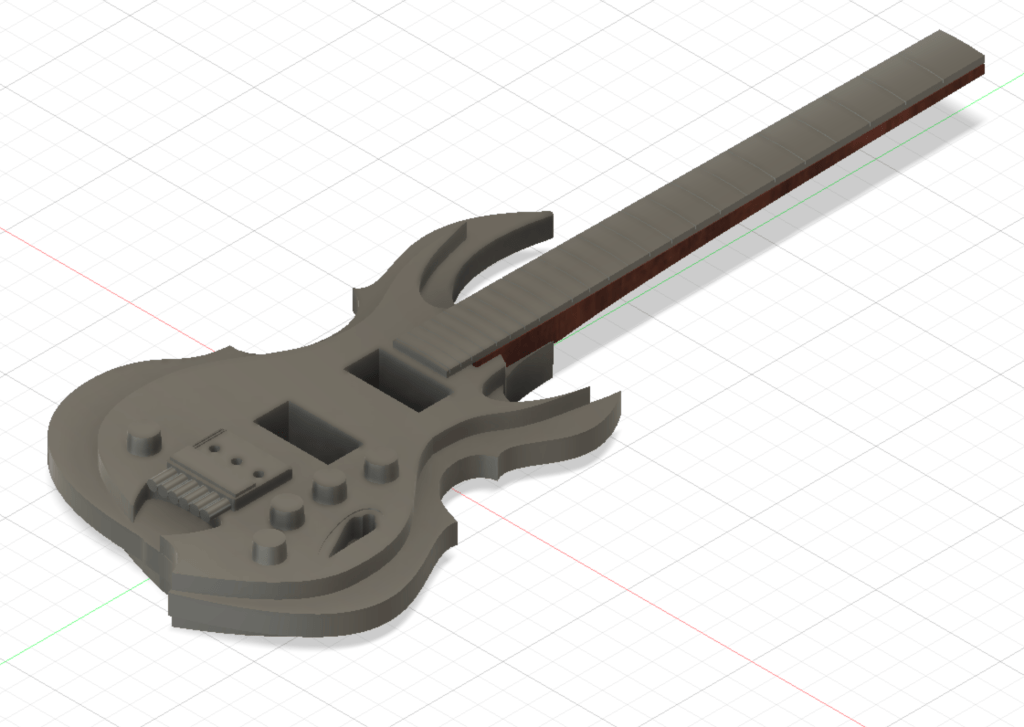

With the guitar 90% done, I had to set it aside so I could use my time and tools for working on a couple of other projects.

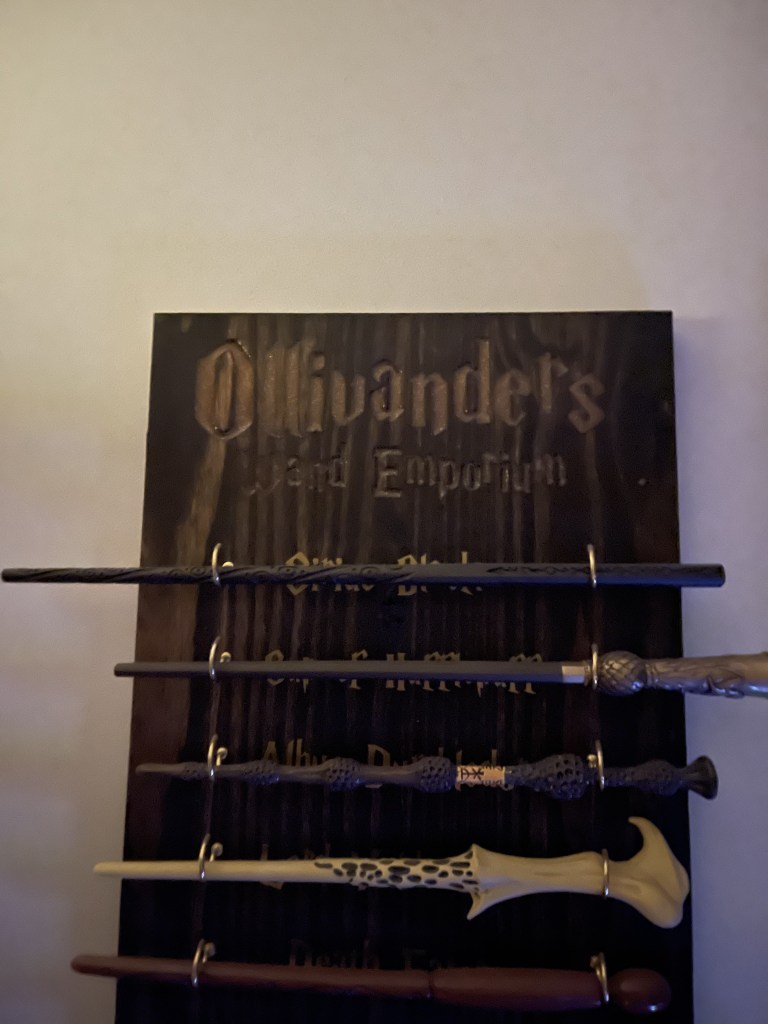

Wand holder

Harry potter is pretty popular with my wife and her family, so of course everone has a wand or seven. My wife thought it would be nice to build a little holder to hang her wands on the wall and label them with which belongs to which character.

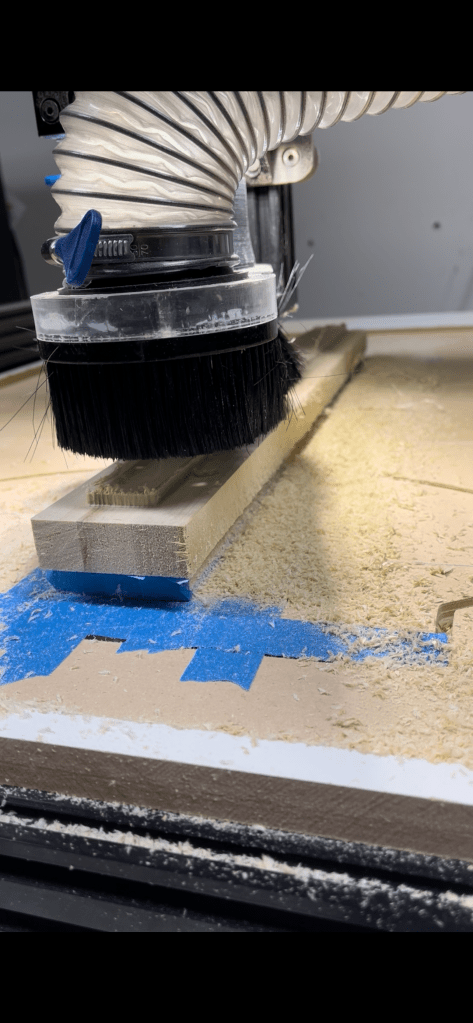

For this one, I used the CNC machine to make quick work of the engraving. From designing to setting up the jobs to mounting the wood and cutting it took about a day. And then we stained it and added the brass hooks to hold the wands. When all was finished my wife added some gold colored resin to the etched words since staining over top of them made them harder to see. I still think it’s hard to see, but she’s happy with it this way. She’s recently tapped me to make one for her sister.

Don’t use power tools with loose hair

I had it reinforced for me to wear my hair tied back when working with tools.

After the job had finished, I homed the CNC machine and bent down to look at something. The threaded rod that controlled the right side of the y axis caught a bit of my hair and wound me down until my face was against the track. I grabbed the gantry and stopped it from moving forward (a Nema 23 motor, 1.8 ft*lbs), hoping the motor would stall out, but it didn’t. I had to search around for a stop/emergancy switch. Couldn’t reach the big red button, but I found that I was able to hit the end-stop for the y axis. After I stopped the progression, I thought I would be able to unwind my hair from the threaded rod but either because of the position I ended up in, the tweek in the squareness of the machine, or the motor’s holding torque, I was not able to get much more than a couple of inches of my hair out. It took me a couple of minutes of feeling around blindly, but I was able to get ahold of a box cutter and had to cut all the hair stuck on the rod while being careful not to cut myself.

If this had been my lathe or sander, or especially my saws, this could have been a disaster. Or deadly. Remember to not work with tools with loose hair! Pulling it back only takes a few seconds. Make a ponytail holder or bandana a standard part of your safety gear. I just strap a ponytail holder over my safety glasses so it’s there when I put them on.

The one that killed my thumb

My wife wanted to make some memorials for her grandfather that she could give out to her family. She took one of this Donald Duck figurines, of which he had many, and some of his funeral flowers and encased them in resin. Once she had the blocks done, she wanted me to make little boxes for them that could be lit up from below with some LEDs.

It was during the making of these boxes that I had a misjudgment in depth and stuck my thumb straight into a table saw. I’ll save the details of the injury for the end of the post.

Warning: graphic and disturbing

Finally this is the biggest reason I’ve not been here. As mentioned above, while working on a project, my thumb got up close and personal with a table saw in full damage mode. First, let me post a couple of pictures of my thumb today so that you can see that the end of the story isn’t tragic.

I have recovered about 75% of strength, 60% of sense of touch, 90% range of movement. Overall I probably ended up in the best scenario of a bad situation.

As soon as the sawblade hit the bone in my thumb, it ripped down along the side of the bone for about an inch before kicking it back out. I was wearing leather work gloves but they offered no protection against the blade. I knew right away that I had recieved a bad cut, even though I didn’t feel it yet, so I gripped my thumb with my other hand and squeezed it tight. I made it into the house and told my wife that I needed to head to the ER. While I waited for her to get her shoes on I took off my gloves and grabbed a gauze from the first aid kit and squeezed it around my thumb tight.

Once at the ER we checked in and still no one but me knew how bad the cut was because the pressure I was holding on it was keeping it from bleeding all over the place. After the intake they gave me a wheelchair because of how pale my face was and they knew I was fighting off passing out. Then back in the waiting room I decided to actually look at how bad it was. I asked my wife if she could see the bone or if it was just muscle or something. At that point she realized it wasn’t just a little “boo boo” cut. That’s when the blood really began flowing.

I asked the intake people for something to help keep the blood from running all over the floor. They asked to look at it. Then they quickly got me back to a room. The nurses kept asking why I hadn’t let them know how bad it was earlier. I just didn’t want to take the place of someone who needed it more. As they gave me more and more morphine I kept appologizing for bleeding all over the room (it’s crazy how many places the blood gets from a cut).

They couldn’t stitch it shut since there was nothing to stitch. So they cleaned it and injected antibiotics (all the way into my palm, that hurt worse than the wound). They wrapped it and then loaded me up with gauzes and coban and an antibiotic to put under the gauze. They give me 3 pain pills and then send me on my way.

The next week I had to set up an appointment with an orthopedic surgeon. But with the gap between the ER visit being about a week, I needed to set up an appointment with another doctor to get some more pain pills. He totally thought I was shopping for pills, until I unwrapped my thumb. He saw it and immediately needed to pull in two more doctors to see it because they were surprised at how bad it was. I got the pills after that.

Orthopedist said that I could either do a skin graft, or just let it heal naturally. With the option between 2 pains plus a surgery bill, I opted for natural healing. It took almost four months for it to finally stop bleeding every day and six or seven months for new skin to completely cover the wound.

Now I can use my thumb normally, mostly. Pressure on the side can hurt because there isn’t much fat or muscle under the skin to cushion the bone. Nerve endings havent quite grown back to all the new skin, so touch is a bit spotty. There are a few places near the edges that have extra sensitivity and feel pain extra stongly. Movement is nearly the same as my other thumb, which was one of the biggest surprises to all my medical caregivers. My grip isn’t as strong as before, but I can’t really quantify that.

Look away now

I know sometimes descriptions just don’t get a real sense of how bad something is, so in the spirit of finalizing my excuse for not being here, I am going to post the pictures of my thumb. If you have a weak stomach, or a strong sympathy response to injuries, I don’t recommend going any further. I have a strong sympathetic response and even fainted once at a book reading (“Guts” by Chuck Palahniuk). I am the kind of person I am warning not to look.